Techniques and Considerations for Demolding in Rotational Molding Process

Demolding is the process of removing the solidified plastic product from the mold after the rotomolding cycle is complete. It requires careful attention to ensure that the product is not damaged or deformed

Feb 29,2024

Feb 29,2024

Light Venus Produces Custom Rotomolded Products with Molded-in Threads

Whether it's for the agricultural, marine, automotive, or other industries, Light Venus can provide custom rotational molding solutions that incorporate molded-in threads, enhancing product functionality, durability, and cost-effectiveness.

Feb 21,2024

Feb 21,2024

Quality Control Measures in Rotational Molding Process at Light Venus

From comprehensive testing procedures and skillful people to compliance with industry standards and customer orientation, Light Venus implements strict quality control policies and uses best quality control measures to ensure the high-quality standard.

Feb 18,2024

Feb 18,2024

Custom Rotational Molding Services for Plastic Toys and Playground Equipment

With a commitment to innovation, quality, and customer satisfaction, Light Venus provides custom rotational molding service for plastic toys and playground equipment.

Feb 12,2024

Feb 12,2024

What is the Total Quality Control in Rotational Molding at Light Venus?

Total quality control in rotational molding involves various aspects, including mold design, material selection, process parameter control, in-process inspection, dimensional inspection, material testing, leak testing, final inspection, and continuous improvement.

Feb 10,2024

Feb 10,2024

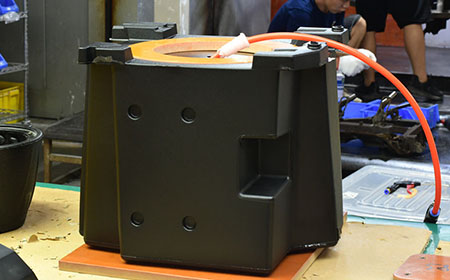

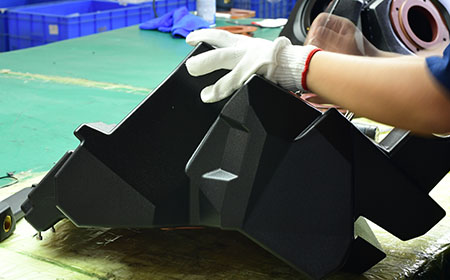

Light Venus Team is full Force with the Production of Rotomolded Products

The production department at our Light Venus is fully committed to delivering quality custom rotational molding products. We are dedicated to creating complete solutions from concept to delivery.

Feb 02,2024

Feb 02,2024

How Rotomolding Factory Can Prevent Rotomolded Products from Deformation?

Preventing product deformation in rotomolding process requires careful consideration of various factors, including material selection, mold design and construction, processing parameters, uniform heating and cooling, and strict quality control.

Jan 29,2024

Jan 29,2024

What are the Factors Affecting the Appearance of Rotomolded Rroducts?

The appearance quality of rotational molding products is influenced by various factors, including material selection, mold design and construction, processing parameters, colorant and additive choices, and surface finish.

Jan 28,2024

Jan 28,2024

How to Enhance Production Efficiency in Custom Rotational Molding?

Enhancing production efficiency in custom rotational molding requires a multi-faceted approach, including material selection, mold design, processing parameters, automation, oven efficiency, cooling processes, and continuous improvement.

Jan 27,2024

Jan 27,2024

Tel: 0086-13632687993

Tel: 0086-13632687993  Email: roto@lightvenus.com

Email: roto@lightvenus.com

Home

Home

You May Also Like

You May Also Like

Tel

Tel

Email

Email

Address

Address