Why Rotational Molding Becomes a Significant Plastic Manufacturing Process?

Rotational molding has become an integral part of modern industrial plastic manufacturing thanks to its versatility, material flexibility, ability to produce stress-free and seamless products, cost-effectiveness, environmental advantages, and assurance of quality and consistency.

Feb 08,2024

Feb 08,2024

What is Rotational Molding Tooling Design Process at Light Venus?

The design process of rotational molding tooling involves several critical steps, including conceptualization, 3D modeling, mold design, consideration of constraints, prototype testing, final mold production, and quality control.

Feb 07,2024

Feb 07,2024

What are the Key Characteristics of Rotomolded Products

The key characteristics of rotomolded products include hollow and seamless products, stress-free structures, complex geometries and customization options, uniform wall thickness, high impact resistance, chemical resistance, and weather resistance.

Feb 05,2024

Feb 05,2024

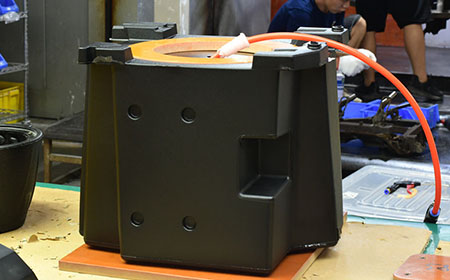

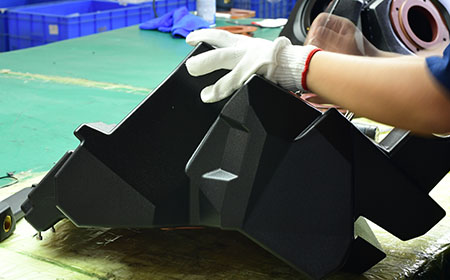

Light Venus Team is full Force with the Production of Rotomolded Products

The production department at our Light Venus is fully committed to delivering quality custom rotational molding products. We are dedicated to creating complete solutions from concept to delivery.

Feb 02,2024

Feb 02,2024

How to Test the Surface Hardness in Rotational Molding Process?

An overview of surface hardness testing in rotational molding process and the guidance on how to test surface hardness effectively.

Feb 01,2024

Feb 01,2024

How To Control Air Flow in Rotomolding Process?

Proper air flow management in rotomolding process is essential for achieving uniform heating, preventing deformation, and ensuring the high-quality of the final rotomolded products

Jan 31,2024

Jan 31,2024

How to Inspect Rotational Molding Tooling Before Production

There are some guidelines on how to inspect the rotational molding tooling prior to production, including visual inspection, verifying dimensional accuracy, evaluating surface finish, checking the gate and ventilation system, and assessing mold material integrity.

Jan 30,2024

Jan 30,2024

How Rotomolding Factory Can Prevent Rotomolded Products from Deformation?

Preventing product deformation in rotomolding process requires careful consideration of various factors, including material selection, mold design and construction, processing parameters, uniform heating and cooling, and strict quality control.

Jan 29,2024

Jan 29,2024

What are the Factors Affecting the Appearance of Rotomolded Rroducts?

The appearance quality of rotational molding products is influenced by various factors, including material selection, mold design and construction, processing parameters, colorant and additive choices, and surface finish.

Jan 28,2024

Jan 28,2024

Tel: 0086-13632687993

Tel: 0086-13632687993  Email: roto@lightvenus.com

Email: roto@lightvenus.com

Home

Home

You May Also Like

You May Also Like

Tel

Tel

Email

Email

Address

Address