Light Venus Expands Production Capacity with Additional Rotational Molding Machines

Light Venus has strategically expanded its production capacity by adding two new rotational molding machines. This initiative directly responds to the dynamic needs of our diverse clientele, enabling us to deliver precise, durable, and innovative rotomolded products with even faster delivery times.

Jun 20,2025

Jun 20,2025

5000 Square Meters Rotomolding Facility Expansion Is Now Operational at Light Venus

Light Venus has officially commenced operations at its newly expanded 5,000-square-meter rotomolding facility. This strategic expansion underscores the company’s commitment to meeting growing global demand for high-quality, durable rotomolded products across industries.

Jun 19,2025

Jun 19,2025

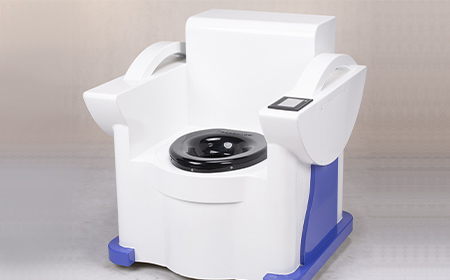

What Are the Common Applications of Rotomolded Products

Rotomolded products are widely applied in industries like industrial equipment, agriculture, farming, automotive, transportation, medical instrument, construction and infrastructure, sport, marine, leisure, boating, and more

Jun 15,2025

Jun 15,2025

What are the Advantages of Rotational Moulding in the Production of Medical Equipment

From its design flexibility and cost - effectiveness to its durability and compliance with medical standards, rotational moulding provides a reliable and efficient solution for businesses in the medical industry

Jun 14,2025

Jun 14,2025

How to Prevent Warping During the Cooling in Rotational Molding Process

Preventing warping during the cooling stage of the rotational molding process requires a comprehensive approach that involves optimizing mold design, carefully controlling the cooling process, selecting appropriate materials, and implementing post - cooling treatments.

Jun 08,2025

Jun 08,2025

Why Are Rotational Molding Processes Widely Used for Large Equipment Enclosures

Rotational molding has become a preferred manufacturing method for large equipment enclosures, such as those for industrial machinery, agricultural equipment, and outdoor enclosures.

Jun 04,2025

Jun 04,2025

Another Custom Rotomolding Project Successfully Kicks Off at Light Venus

Light Venus proudly announces the kickoff of a new custom rotomolding project, showcasing expertise in creating high-performance, corrosion-resistant automotive parts

May 31,2025

May 31,2025

Key Considerations for Installing Rotomolding Molds on Rotomolding Machines

The installation of rotomolding molds on rotomolding machines in a rotomolding factory requires careful attention to detail, strict adherence to safety protocols, and proper use of equipment and techniques.

May 27,2025

May 27,2025

How to Prevent Sticking and Jamming in Roto Molding Process

Practical solutions to addressing sticking and jamming issues in the roto molding process, including understanding the root causes, choosing the right materials and processes, maintaining the equipment, and investing in staff training.

May 19,2025

May 19,2025

Tel: 0086-13632687993

Tel: 0086-13632687993  Email: roto@lightvenus.com

Email: roto@lightvenus.com

Home

Home

You May Also Like

You May Also Like

Tel

Tel

Email

Email

Address

Address