What are the Causes of Sticking and Jamming in the Rotational Molding Process

The cause of sticking and jamming in rotational molding process includes mold surface condition, material factor, process parameter imbalances and improper mold design. By understanding the causes of sticking and jamming in the rotational molding process and implementing appropriate preventive measures, rotational molding factories can effectively reduce the occurrence of these issues.

May 14,2025

May 14,2025

What Are the Key Post-Demolding Inspection Points in Rotational Molding?

Key post-demolding inspection points in rotational molding include surface quality, wall thickness, dimensional accuracy, structural integrity, color and appearance consistency, and material compatibility.

May 12,2025

May 12,2025

What Are Some Tips for Optimizing Heating Temperature in Rotational Molding

Some useful tips to optimize heating temperature for improving product quality and production efficiency. including selecting the right resin, conducting thorough pre-mold preparation, monitoring and controlling the oven temperature, optimizing the heating time, and considering the cooling process.

May 11,2025

May 11,2025

Light Venus Delivers High-Precision Rotomolded Parts to Global Automotive Customer

Light Venus is delighted to announce the successful delivery of a meticulously crafted batch of high-precision rotomolded parts to a leading automotive client. These protective housings are engineered to meet the most exacting industry standards in terms of strength, weight optimization, and environmental resilience.

May 02,2025

May 02,2025

How Rotomolded Products Quality Issues Are Addressed Quickly at Light Venus

By addressing rotomolded plastic parts quality issues proactively, Light Venus delivers durable, precision-engineered solutions for the OEM customers across the world.

Apr 26,2025

Apr 26,2025

How to Choose the Right Cooling Method for Rotomolded Products

Choosing the right cooling method for rotomolded products is a critical decision that affects the quality, efficiency, and cost-effectiveness of the manufacturing process

Apr 22,2025

Apr 22,2025

Light Venus Shipped Over 2000 PCS Custom Rotomolded Speaker Enclosures This Week

This week, Light Venus accomplished a significant milestone by successfully shipping over 2,000 meticulously custom - engineered rotomolded speaker enclosures to a preeminent OEM audio equipment manufacturer.

Apr 17,2025

Apr 17,2025

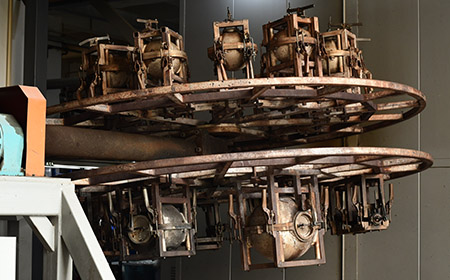

Custom Rotomolding Solutions for Plastic Products with Precision and Performance

Light Venus excels in crafting high-end customized plastic products meticulously designed to fulfill unique requirements and project specifications.

Apr 15,2025

Apr 15,2025

How Does the Durability of Rotomolded White Polyethylene Plastic Globe Lampshade

The durability of rotomolded white plastic globe lampshades offer a blend of impact resistance, weather resilience, and low maintenance that makes them a reliable choice for both indoor and outdoor lighting.

Apr 08,2025

Apr 08,2025

Tel: 0086-13632687993

Tel: 0086-13632687993  Email: roto@lightvenus.com

Email: roto@lightvenus.com

Home

Home

You May Also Like

You May Also Like

Tel

Tel

Email

Email

Address

Address